Customized Screen Protector Supplier-Gtel

Gtel is a Customized screen protector supplier that offers Customized-size glass screen protectors for mobile phones, tablets, laptops, watches, cars, and other device screens. A customized screen protector is a sheet of glass or plastic that is cut to fit the dimensions of a specific device’s screen.. Which meets your specific needs including different dimensions, corner radius, and cutting holes if have any.

Customized screen protectors can also be printed with customized designs or logos, which can make your device more personalized and unique. At the same time, we also provide functionality customization like Anti-blue light glass, Anti-glare glass, Anti-spy glass, and antibacterial inspection.

Our team of Quality Control Specialists put each screen protector through a series of tests to avoid any scratching, impact, fingerprinting, dust, or other common issues.

1.Production Process of Customized Size Screen Protector

1.1 Measure customized screen protector dimensions

Measure your screen: measure your screen according to the screen type you have.

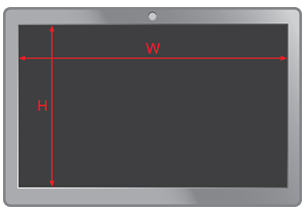

Raised Bezel

These screens have a raised frame around the edges.

Measure the height (h) and width (w) of the screen’s viewable area, making sure to measure within the bezel.

1.2 Scanning and Drawing

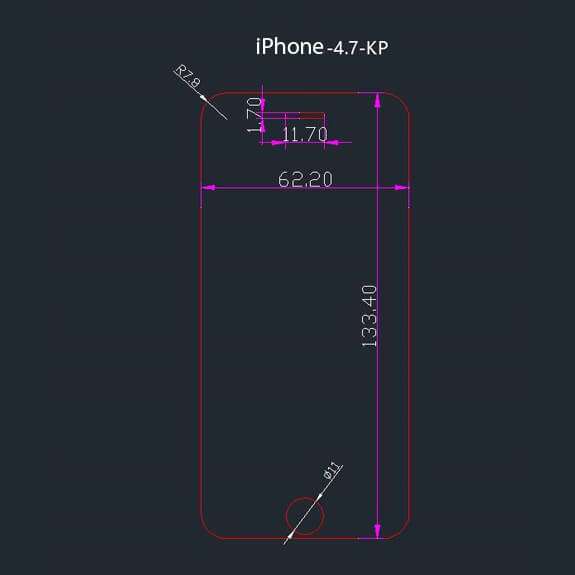

Such as the customized is different from the standard models, please provide physical samples to scanning or your design drawings.

Such as the customized is different from the standard models, please provide physical samples to scanning or your design drawings.

Make the design drawing based on your height (h) and width (w) measurements, and some cutouts may need to be scanning and drawing too.

- Scanning:if you can offer the physical samples, we can scanning it and then drawing.

- Drawings: if you can offer the design drawings, we can make it according to your drawing.

1.3 Select the right raw material:

- Level 1: Corning glass; Schott glass

- Level 2: Asahi glass; Nippon glass; High Aluminosilicate glass

- Level 3: CSG glass

The Level 1 glass much expensive than level 2 glass, but the quality difference is very small based on normal glass.

We recommend the Asahi glass as the first choice unless customer definite glass brand requirement or request 0.15mm or 0.1mm thickness glass

1.4 Open Mold:

- The glass will be needed to do customized cutting based on a drawing.

- And the AB glue needed to do customized cutting based on the glass dimensions.

1.5 Make Sampling:

The production line process:

- Gtel select top quality imported raw materials

- Incoming inspection and take spray coating protection

- Raw material cutting based on different request

- Full-automatic high precision CNC glass cutting

- CNC engraving and milling

- Ultrasonic wave cleaning

- Automatic constant temperature glass tempering furnace with more than 4 hours

- Using the polishing machine, get the perfect curved edge

- Repeat Ultrasonic wave cleaning and drying

- Silk printed coating (different color based on requirement)

- Laminating the AB glue with the glass backside

- In the dust-free workshop 100% QC

- Use spraying equipment plating anti-fingerprint oil

- Our QC team will do 100% QC before packing

- Packing according to customer details requirement